Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Is there "sunshine" in the plant factory? Yes! Where does "sunshine" come from? From some special plant lights!

The first plant lamps used in plant factories are incandescent lamps, high pressure sodium lamps, metal halide lamps, fluorescent lamps and other traditional lamps, and the most popular plant light source is LED light source. Since the birth of LED light source, due to its significant innate advantages, it has been quickly favored by researchers and become an efficient production tool.

There are essential differences between LED light source and traditional lamps in the principle of luminescence.

Incandescent lamps, by heating the filament, emit light like a red-hot iron when it is hot enough, so that they convert most of the electric energy into heat and only a little into light.

High-pressure sodium lamp, gold halide lamp, fluorescent lamp, etc. are gas discharge lamps, which accelerate the electrons in the discharge tube through the external electric field and stimulate the discharge of gas (including some gaseous metals), leading to atomic luminescence. The spectral characteristics are mainly determined by the characteristics of the gas composition itself.

Leds are solid-state light sources, and at their core are PN junctions made of semiconductors. P-type semiconductors (with higher concentrations of holes) and N-type semiconductors (with higher concentrations of free electrons) are usually made of different semiconductor compounds, and the region of space charge formed at their junction is called a PN junction. Luminescence by electron and hole migration and recombination of PN junction. The luminescence properties of PN junction are different from the compounds that make Pn junction. So what are the innate advantages of LED plant lights?

First, LED plant lighting is efficient and energy saving. After LED lamps are applied in agriculture, the use density of lamps is very high compared with that of general lighting, especially for plants with high light demand, and the electricity power of each square meter planting area is as high as 500-1000 W. This puts forward a strict requirement for the electro-optic conversion efficiency of plant lamp. At present, the electro-optic conversion efficiency of LED plant lamp is more than 20 times that of incandescent lamp, 3 times that of fluorescent lamp, and nearly 2 times that of high pressure sodium lamp and gold halide lamp. Therefore, the application of LED plant lights can greatly reduce electricity consumption, thus achieving energy saving. Second, LED spectral bands cover a wide range, easy to obtain monochromatic light and full spectrum.

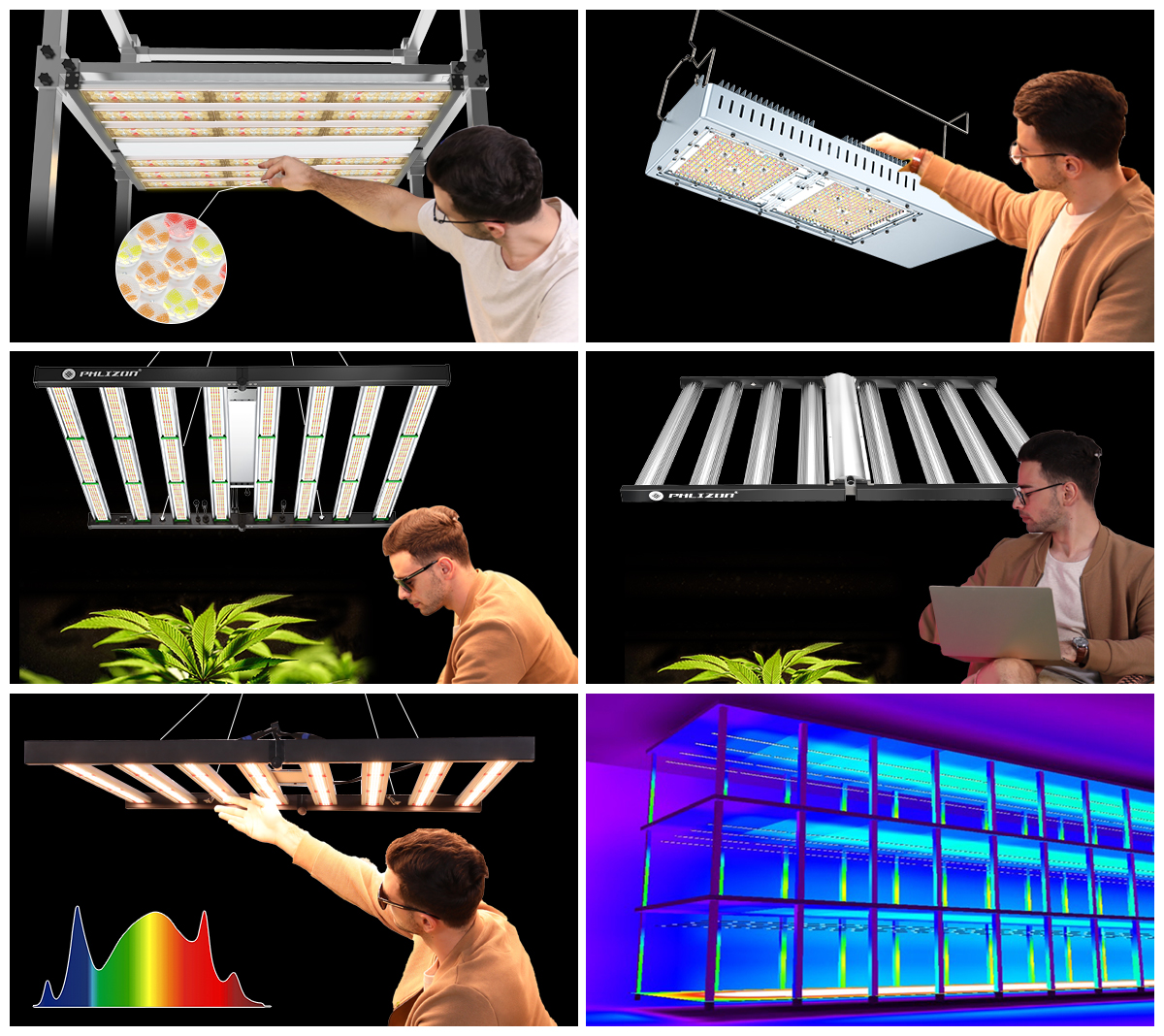

Currently, leds can cover the wavelength range of 200-950 nm, and there are dozens of single-color leds. And the monochromatic LED chip can stimulate phosphor to widen the half-wave width of monochromatic light, or monochromatic light composite spectrum, or obtain the full spectrum of white light. This provides very favorable experimental conditions for studying the light absorption of different plants, and enables the spectral customization of different plants to provide the best light formula for plants. Third, Led Plant Light intensity, spectrum can be adjusted.

LED is a current driven light source, its brightness increases with the increase of the current. Therefore, the corresponding brightness can be obtained by adjusting the power output current of the driving LED. The function of spectrum adjustment can be realized by controlling the current size of LED with different light color. At present, the plant lamps with adjustable spectrum in the market are mainly used for scientific research, and the plant lamps with adjustable intensity have been widely used in production.

Fourth, LED heat less, can be close contact with plants without plant leaves and operators burning problems. The rapid development of indoor multilayer planting technology is also mainly due to this feature of LED plant lights. Fifth, LED long life, light decay, high reliability. The theoretical life of LED is up to more than 100,000 hours. The life of LED plant lights can exceed 50,000 hours if the LED working temperature can be controlled under the right temperature. Currently, high-end LED plant lights have a five-year warranty, and the light decline is still less than 10% after 36,000 hours of operation. Fluorescent lamps typically lose up to 30% of their light after 10,000 to 15,000 hours of operation.

Sixth, LED has strong controllability and great potential for intelligent control. Traditional lamps, such as high pressure sodium lamps, need more than 5 minutes to reach stable working state from power on, and they need about 10 minutes of cooling after power off before starting again. And LED response speed is extremely high, the rapid switching conditions of 30,000 times per second can still work.

Seventh, the use of high safety, high transport reliability. Traditional lamps and lanterns are mostly glass shells, which are inevitably damaged by broken glass in the process of transportation and use. LED as a solid light source, vibration, drop, impact and other high tolerance, safe and reliable.

Eighth, diversified forms of lamps and lanterns. The traditional light source is usually a bulb type, and when it is made into a plant lamp, a reflector is often added to shine its light down on the target plant. LED plant lights can not only be made into downward glow top light lamp, but also can be made into 360 degrees of light close to the plant between the plant fill light lamp.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.